Electrical Safety Auditor in Jaipur

Electrical Safety Audit in Jaipur

Electricity is a good servant but a bad master

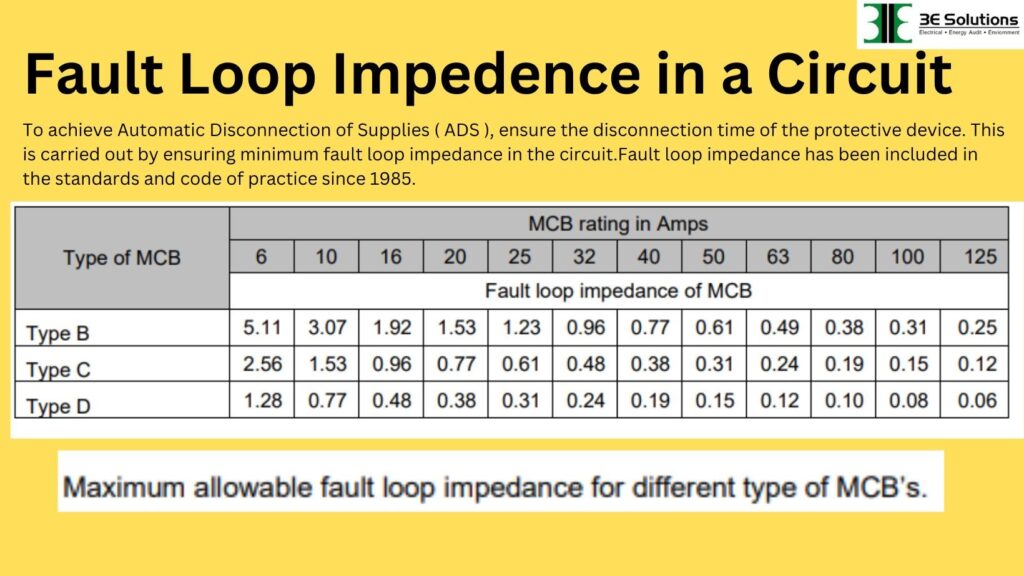

Electrical hazards still threaten safety of people and property in the form of shocks, burns, injury, fire and explosion. Industries and installation in no way can avoid uses of electrical energy and hence carry risks related to human errors, damages of equipment, uses of incorrect specification materials and bad power quality. With electricity having become an indispensable part of our life, electrical risks are to be managed carefully through Electrical Safety Audit. We have conducted electrical safety audit of numerous installations in Jaipur and all Rajasthan. We carry out Thermography survey, Earthing Survey, Fault Loop Impedence survey and Lightning Protection Survey for installations with required tools and tackles in the electrical safety audit in Jaipur and all Rajasthan.

ELECTRICAL SAFETY AUDIT SCOPE

In process industries, fires due to electrical reasons are common, especially in industries that handle flammable chemicals which is key focus of electrical safety auditor. In service industries business interruption losses due to electrical hazards (fire in server room, damage of expensive communication equipment, loss of data, fire in cable gallery, etc.) could be substantial

The scope varies in type of industries however, the typical electrical safety audit checklist in Large industry is as below :

- Physical inspection to identify electrical hazards (shock, fire, explosion, overloading)

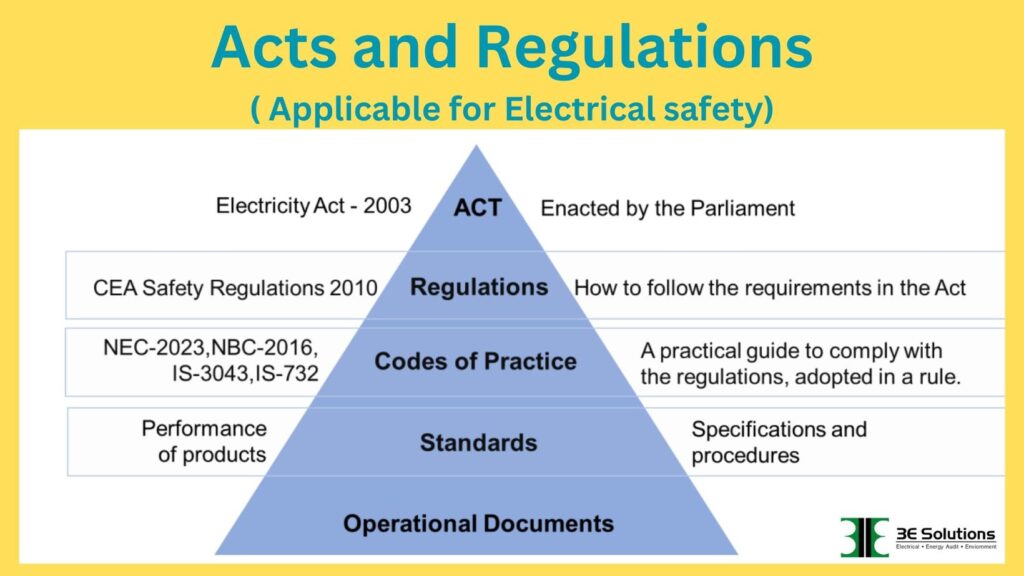

- Statutory compliances like CEA-Central Electricity Authority, Indian Electricity Rules.

- Review of plant lightning protection system – Need, adequacy and maintenance)

- Review of hazardous area classification and selection of flameproof electrical equipment in the plant, including maintenance aspects (if applicable)

- Review of electrical preventive maintenance system (including tests, PTW system, documentation, history cards, etc).

- Review of electrical accidents and near misses in the plant to identify the root causes

- Review of electrical systems & procedures (PTW, interlocks, lockout tags, etc).

- Earthing System and verification of earthing by measurement and recommendations.

- Review of the importance given to electrical safety in the company safety policy, safety committee, continuous electrical risk identification, etc.

- Assessing the integrity of insulation of cables by carrying out insulation resistance tests on a sample basis

Methodology

Following are the steps while conducting Electrical Safety Audit

- Pre-Audit Questionnaire

- Audit- Physical Inspection; Thermography, Power Quality Audit, Harmonic Analysis

- Discussions

- Document review

- Management Briefing