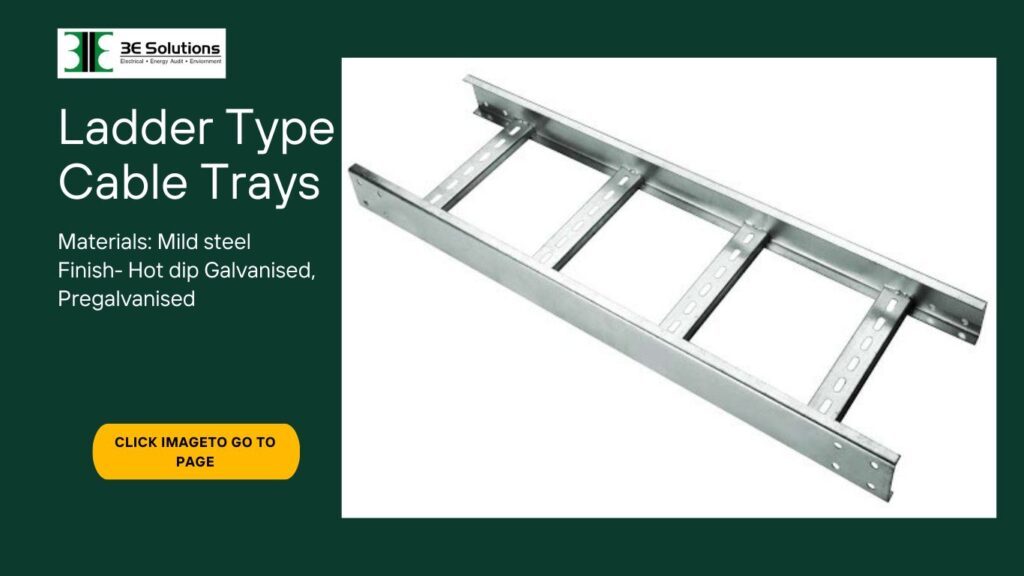

LADDER TYPE CABLE TRAYS

3E Solutions is leading ladder type cable tray manufacturer in Jaipur, Rajasthan. Generally used in applications with intermediate to long support spans 12 to 30 feet. A ladder cable tray without covers permits the maximum free flow of air across the cables which allows the heat produced in the cable’s conductors to effectively dissipate. Under such conditions, the conductor insulation in the cables of a properly designed cable tray wiring system will not exceed its maximum operating temperature.

Construction of Ladder type cable trays

Ladder type cable trays are a widely preferred solution for routing and supporting power and control cables in commercial and industrial installations. Their robust construction and open design make them suitable for heavy-duty cable management, especially where airflow, cable heat dissipation, and future expandability are key considerations.

A typical ladder type cable tray consists of two longitudinal side rails connected by individual rungs spaced at regular intervals, generally 250 mm or 300 mm apart. These rungs serve a dual purpose: they provide structural support for the cables and act as convenient tie-down points. The construction material is usually galvanized steel, stainless steel, or aluminum, depending on the installation environment. In corrosive or outdoor environments, hot-dip galvanized or powder-coated finishes offer added protection against environmental degradation.

One of the critical features of ladder type cable trays is their ability to handle high-capacity cable loads while maintaining proper alignment and spacing. The open design ensures continuous ventilation, which reduces the risk of overheating and allows for efficient cable maintenance and inspection. This makes them particularly ideal for high-power electrical installations, including those with single-core power cables.

The rungs play an essential role in non-horizontal or inclined tray runs, where gravity or movement could cause the cables to shift. By securely anchoring the cables to the rungs using cable ties or clamps, installers can ensure mechanical stability and reduce the likelihood of cable movement over time. In horizontal runs, rung tie-downs are equally important when exact cable positioning must be maintained—for example, in applications with limited space or where electromagnetic interference (EMI) is a concern.

For single conductor cable installations, especially in three-phase systems where each conductor is run separately, proper securing is absolutely essential. During fault conditions, such as a short circuit, powerful magnetic forces are generated that can cause unrestrained cables to jump out of the tray, posing serious safety hazards and potential equipment damage. Therefore, anchoring the cables to the rungs becomes a critical safety requirement in such scenarios.

In conclusion, the construction of ladder type cable trays emphasizes strength, flexibility, and safety. Their engineered design allows for secure, organized cable runs while meeting industrial demands for durability and performance. Whether in substations, control rooms, or manufacturing facilities, ladder type cable trays continue to be a foundational element in modern electrical infrastructure.

Cables may exit or enter the ladder type cable trays through the top or the bottom of the cable tray where the cables enter or exit conduit, the conduit to cable tray clamps may be installed upright or inverted to terminate conduits on the top or bottom of the cable tray side rail. The most common rung spacing for ladder cable tray is 9 inches. This spacing may be used to support all sizes of cables.

Standard Length | In Standard length of 2.5 mtrs (2500 mm) |

| Width | 50 mm, 100 mm, 150 mm, 200 mm, 300 mm, 450 mm ( Can be customised) |

| Thickness | 1.6 mm to 2 mm |

| Height | 50 mm, 75 mm, 100 mm ( Can be customised) |

| Materials | Mild Steel conforming to IS |

| Finish | Hot Dip Galvanized, Enamel painted, Powder Coating, Self-colored, Pregalvanised ( PG) |